Product

Minimal Contamination in Plasma Process

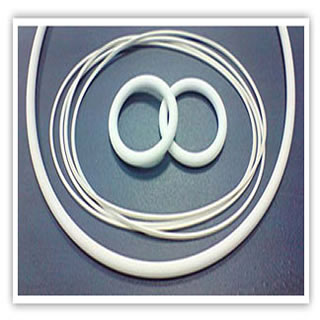

Product ID: Puruz P325 perfluoroelastomer parts

Specifically designed for plasma and gas deposition processes, the Puruz P325 features excellent seal reliability and minimal contamination. Its properties include minimal particle generation in oxygen and fluorine containing plasmas as well as excellent chemical compatibility. In addition, the Puruz P325 is offered in various geometries and cross sections and is particularly well suited for static and dynamic applications such as slit valve door, gas feed-through, chamber lids, etc. It remains stable at service temperatures as high as 275°C. Puruz P325-made parts are adapted for Class 100 post-cleaning and packaging.

Applications:

- Slit valve doors

- Gas inlet seals

- Window seals

- KF fitting seals

- Gas feed-through seals

- Chamber seals

- Isolator valve seals

- Lid seals

Recommended Processes

- Deposition: CVD, APCVD, HDPCVD..., PVD

- Plasma etching: Oxide, Metal, Poly

- Ashing

- Ion implant

- Remote plasma cleans

Features:

- Excellent oxygen, chlorine, and fluorine compatibility

- Minimal particle generation

- Excellent chemical and physical properties

- Unlimited design flexibility

- Low out-gassing

| ||||||||||||||||||||||||||

Contact Detail

| Address: | No. 41, Wu-Chuan-Wu Road, New Taipei Industrial Park, New Taipei City 24888, Taiwan |

| TEL: | +886-2-2298-8556 |

| FAX: | +886-2-2299-2189 |

| Email: | mfc@mfc.com.tw |

| URL: | http://www.mfc.com.tw |

| ZIP: | 24888 |