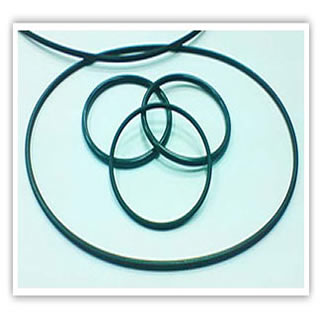

Product

Excellent High Temperature Resistance in Diffusion Process

Product ID: Puruz P340

Puruz P340 is a special compound which exhibits high temperature resistance and is well-suited for both static and dynamic applications. It remains stable at service temperatures as high as 324°C, and has a low compression set for use in extreme diffusion, CVD, and dry processes. Class 100 post-cleaning and packaging is adapted for parts made from Puruz P340.

Applications:

- Valve seals

- V-seals

- Bell jar seals

- Filter seals

- Chamber seals

- Lid seals

- Gas inlet seals

- Isolator valve seal

- End point windows

- Slit Valve seals

- Window seals

- KF fitting seals

Recommended Processes

- Deposition: CVD, APCVD, HDPCVD..., PVD

- Plasma etching: Oxide, Metal, Poly

- Ashing

- Ion implant

- Remote plasma cleans

- Diffusion

- Rapid thermal process

- Annealing

Features:

- Excellent high temperature resistance

- Excellent plasma resistance

- Low out-gassing

| ||||||||||||||||||||||||||

Contact Detail

| Address: | No. 41, Wu-Chuan-Wu Road, New Taipei Industrial Park, New Taipei City 24888, Taiwan |

| TEL: | +886-2-2298-8556 |

| FAX: | +886-2-2299-2189 |

| Email: | mfc@mfc.com.tw |

| URL: | http://www.mfc.com.tw |

| ZIP: | 24888 |